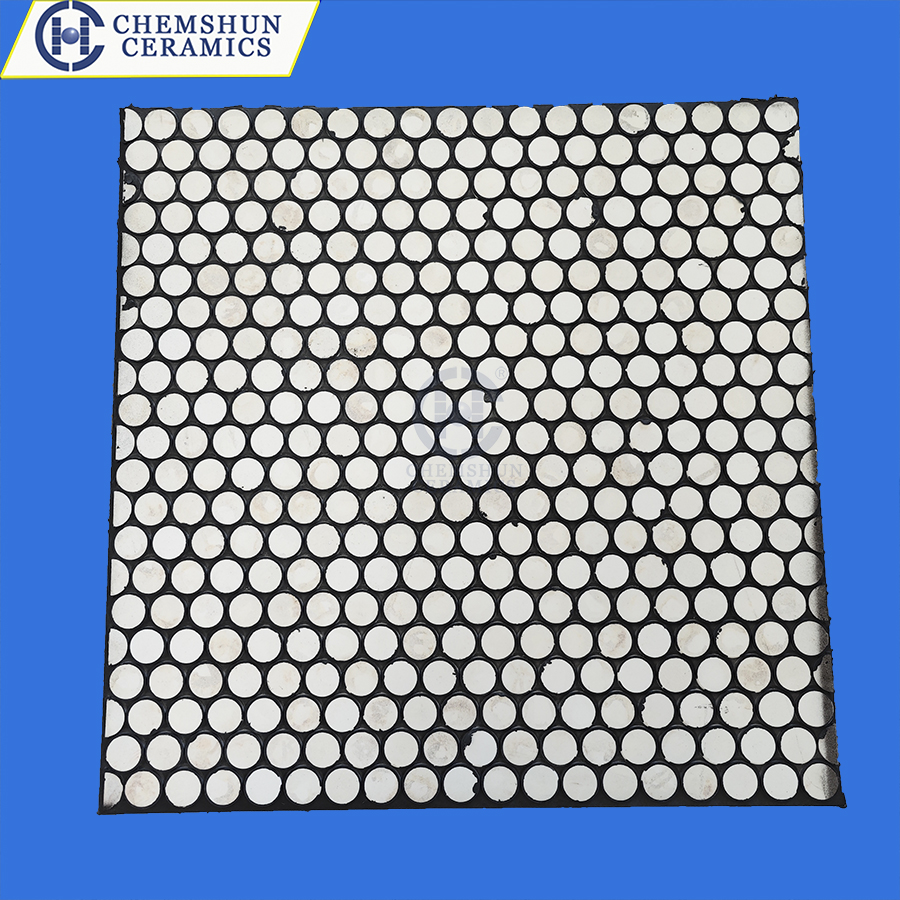

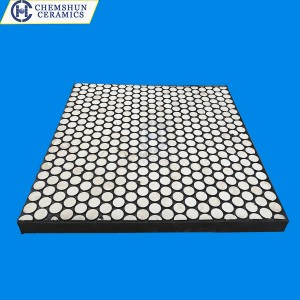

Alumina Zylinder Vulkaniséiert als Keramik Gummi Placke

Eegeschaften

1) Héich Hardness.

2) Superior Abrasion Resistenz.

3) Korrosioun a chemesch Resistenz.

4) Liicht Gewiicht.

5) Kann an all Zort vun Gummistécker Panel oder conveyor vulkanized ginn.

Applikatioun an Industrien

| Industrie | Equipement System | Equipement Deeler |

| Zement | Pre-Mëschungssystem fir Kalksteen a Rohbrennstoff ofbriechen | Chute, Bunker, Pulley lagging, Auslaafkegel |

| Raw Mill System | Feed Chute, Haltring, Scraper Plack, Sigelring, Pipeline, Eemerschutz, Zyklon, Pulverkonzentratorkierper, Bunker | |

| Zement Mill System | Chute, Bunker, Fan Vane Rad, Fan casing, Cyclone, Circular duct, conveyer | |

| Ball Mill System | Pulverizer Auspuff Kierper a Vane Rad, Pulver Konzentrator Kierper, Pulveriséierter Kuel Pipeline, Hot Air duct | |

| Sintersystem | Inlet/Outlet Bend, Windwäertplack, Cyclone, Chute, Staubs Collector's Pipe | |

| Afterheat System | Separator Pipeline a Mauer | |

| Stol | Matière première fidderen System | Hopper, Silo |

| Batching System | Vermëschung Bunker, Mëschung barrel, Mëschung Scheif, Scheif pelletizer | |

| Sinter Material Transport System | Hopper, Silo | |

| Dedusting an Ash Offlossquantitéit System | Dedusting Pipeline, béien, Y-Stéck | |

| Kocksystem | Kock Hopper | |

| Mëttel-Vitesse Millen | Kegel, Trennbüffelen, Ausgangsleitung, Pipeline vu pulveriséierte Kuel, Brennerkegel | |

| Ball Mill | Classifier, Cyclone separator, béien, bannenzege Réibau vun Pudder konzentréieren | |

| Thermesch Kraaft | Kuel Ëmgank System | Eemer Rad Maschinn, Kuel Hopper, Kuel Feeder, Orifice |

| Ball Mill System | Separator Päif, Ielebou a Kegel, Kuel Millen Ielebou an riichtaus eraus | |

| Mëttel-Vitesse Millen | Kuel Mill Kierper, Trennung buffles, Kegel, Pipeline, Ielebou | |

| Fall Mill | Pulveriséierte Kuel Pipeline an Ellbog | |

| Dedusting System | Dedusting Pipeline an Ielebou | |

| Äschen Auslaaf System | Fan Duster Schuel, Pipeline | |

| Port | Transport Material System | Eemerrad Maschinn Scheif an Hopper, Transfer Point Hopper, Unloader Hopper, |

| Schmelzen | Transport Material System | Messträger, Koksträger, Vibratiounsschirmschnouer, Kappventil, Zwëschebehälter, Schwanzbehälter |

| Batching System | Batch Hopper, Vermëschung Maschinn | |

| Verbrenne System | Äschen Eemer, Pompel calcine Rouer, Hopper | |

| Dedusting System | Dedusting Pipeline an Ielebou | |

| Chemesch | Transport Material System | Hopper, Silo |

| Dedusting System | Dedusting Pipeline an Ielebou | |

| Veraarbechtung Equipement | Vibromill liner | |

| Kuel | Kuel Ëmgank System | Eemer Rad Maschinn, Kuel Hopper, Kuel fidderen |

| Kuel wäschen System | Hydrocyclone | |

| Biergbau | Transport Material System | Hopper, Silo |

Technesch Informatiounsblat

| S.Nr. | Attributer | Eenheet | CHEMSHUN 92 I | CHEMSHUN 92 II | CHEMSCHUN 95 | CHEMSHUN ZTA |

| 1 | Alumina Inhalt | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Dicht | g/cc | ≥3,60 | ≥3,60 | >3,65 | ≥4.2 |

| 3 | Faarf | - | Wäiss | Wäiss | Wäiss | Wäiss |

| 4 | Waasser Absorptioun | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Flexural Kraaft | Mpa | 270 | 300 | 320 | 680 |

| 6 | Moh's Dicht | Grad | 9 | 9 | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 85 | 87 | 90 |

| 8 | Vickers Hardness (HV5) | kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Frakturzähegkeet (Min) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Kompressiv Kraaft | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Thermesch Expansiounskoeffizient (25-1000ºC) | 1×10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Maximal Operatioun Temperatur | ºC | 1450 | 1450 | 1500 | 1500 |

Chemshun Keramik Virdeeler

1) Professionell technesch Equipe fir CAD Designs ze leeschten.

2) Professionell Installatiounsteam fir Installatiounsservice ze leeschten.

3) Gutt etabléiert Prozess no international Standarden.

4) Akzeptéieren d'Standard a pre-engagéiert Fliesen.

Produit Tags

Schreift Äre Message hei a schéckt en un eis